1. Keywords:

Ship, equipment, shock, test, simulation, evaluation, structure, explosion, underwater, in-cabin, air, deep water, measurement, impact machine, floating impact platform, vibration damper, buffer and vibration isolator;

2. Test facility: Explosion testing pool

Introduction: The test facility has a maximum test charge of 70kgTNT. The auxiliary plant is equipped with a dock and a crane. The maximum depth of the dock is 8m, and the maximum lifting capacity of the crane is 50t.

Conventional test items: Underwater explosive power test on charge; explosion resistance test and dynamic response test on various surface and underwater targets.

3. Test equipment: Medium-sized high-impact shock machine for ship equipment

Introduction: The testing facility can be used for standard impact assessment test on the equipment according to MIL-S-901D and GJB150.18-1986, impact test on 120 kg~2.7 t ship equipment and components according to the standard, and experimental investigation on impact resistance of equipment and systems.

Conventional test items: Impact assessment test on ship equipment; impact strength test on elastic components; experimental investigation on impact resistance of equipment and systems.

4. Test equipment: Horizontal medium-sized high-impact shock machine

Introduction: The shock machine has a maximum load capacity of 8t, and its anvil has a maximum impact speed of 5.5m/s. The machine can be used for horizontal impact test and experimental investigation on impact resistance of various marine equipment, components and systems.

Conventional test items: Impact assessment on underwater equipment and systems; horizontal impact test on equipment and systems; horizontal impact strength test of elastic components; experimental investigation on horizontal impact resistance of equipment and systems.

5. Test equipment: Drop hammer impact testing machine

Introduction: The testing machine has a load capacity of 5 kg~20 t, the maximum impact speed of 10m/s, and the maximum impact force of 10MN. It can be used for impact performance test and assessment on electronic components, damping components, flight equipment and other ship parts, as well as various types of non-standard impact tests.

Conventional test items: Impact performance and assessment test on various elastic components; non-standard impact assessment test on ship equipment; drop impact test on flight equipment; puncture impact test on various data protection containers (black boxes); impact performance test on materials.

6. Test equipment: Small floating impact platform

Introduction: The test platform has a maximum load capacity of 8t, and can be used for the impact assessment test on ship equipment with a mass of less than 8t, as well as the experimental investigation on impact resistance of ship equipment, systems, components, etc.

Conventional test items: Impact assessment test on ship equipment; impact assessment test on equipment base; impact assessment test on external equipment; impact performance and assessment test on elastic components; experimental investigation on impact resistance of ship equipment.

7. Test equipment: Standard floating impact platform

Introduction: The test platform can be used for standard impact assessment test on equipment according to GJB150.18-1986, impact test on 2.7t~50t ship equipment, systems, components, etc. according to the standard, and experimental investigation on impact resistance of ship equipment, systems, components, etc..

Conventional test items: Impact assessment test on ship equipment; impact assessment test on equipment base; impact assessment test on external equipment; impact performance and assessment test on elastic components; experimental investigation on impact resistance of ship equipment.

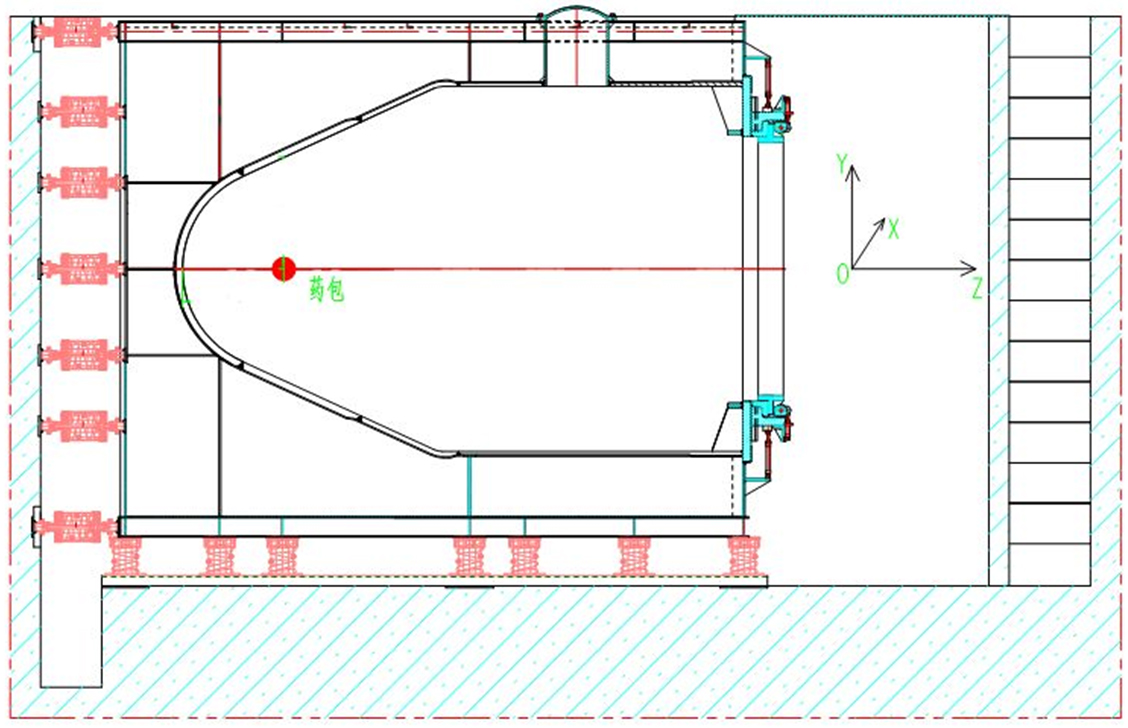

8. Test equipment: Pressure tank for deep-water explosion test

Introduction of experimental facilities: The pressure tank can be used for underwater explosion test under a water pressure of 0~6 MPa. It has an inner diameter of 7m and a maximum test charge of 1kgTNT, and is provided with a water purification system, a lighting system, and an electrical and optical measurement system.

Conventional test items: Explosive power test of charge in deep water; explosion resistance test on structure in deep water; full simulation condition test on ship structure; explosion resistance test on underwater weapon scale model.

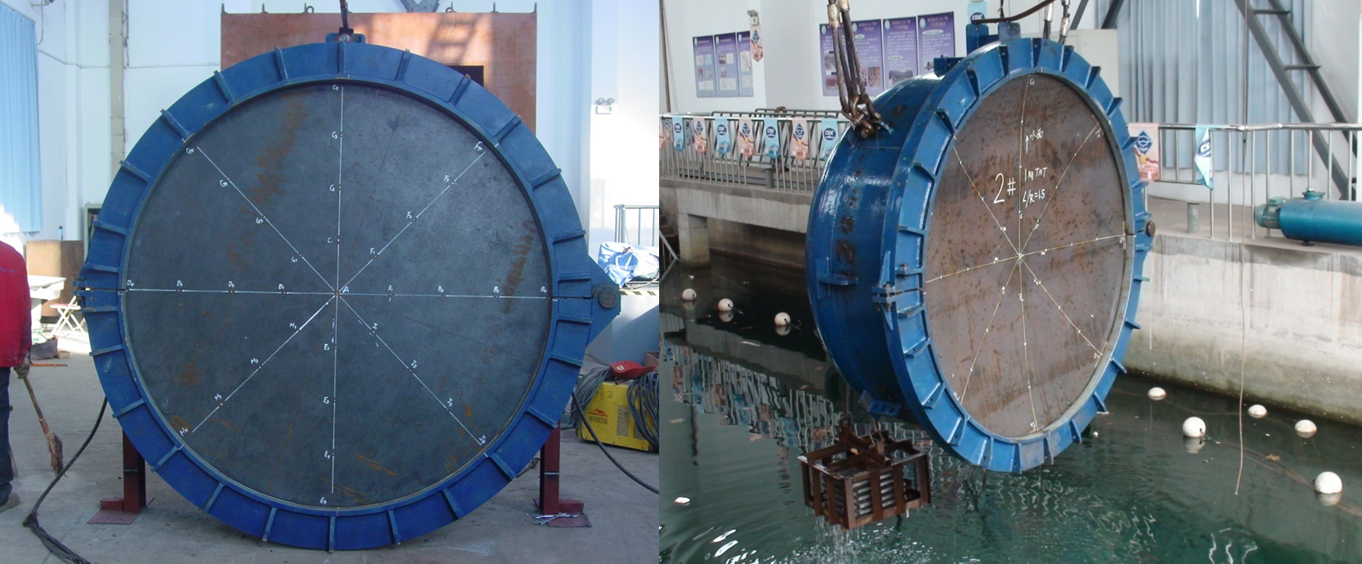

9. Test equipment: In-cabin explosion test device

Introduction: The test device has a maximum test charge of 10kgTNT, and can be used for test and assessment on explosion resistance of anti-explosion doors, anti-explosion windows and anti-explotion bulkhead structures in the cabin. The maximum dimensions of the model is 2.5m×2.5m.

Conventional test items: Explosion resistance test on anti-explosion doors/windows/bulkheads; various anti-explosion assessments and tests.

10. Test equipment: Underwater explosion test device for large-sized grillage structures

Introduction: The test device can be used for underwater experimental investigation or assessment on ship grillage structures and scaled models with a maximum size of 2.4m×2.4m. It also can serve as the standard power target of large charge.

Conventional test items: Intense underwater explosion test on horizontally-installed single/double-layer grillage structures; intense underwater explosion test on vertically-installed single/double-layer grillage structures.

11. Test equipment: Test device for standard power target of large charge

Introduction: The test device can be used for evaluating and measuring the damage efficiency and power of the charge to the target under underwater non-contact and contact explosion conditions. The maximum test charge is 1kg, the maximum diameter of the target plate is 2m and the maximum thickness is 10mm.

Conventional test items: Underwater non-contact explosive power test on charge; underwater contact explosive power test on charge.

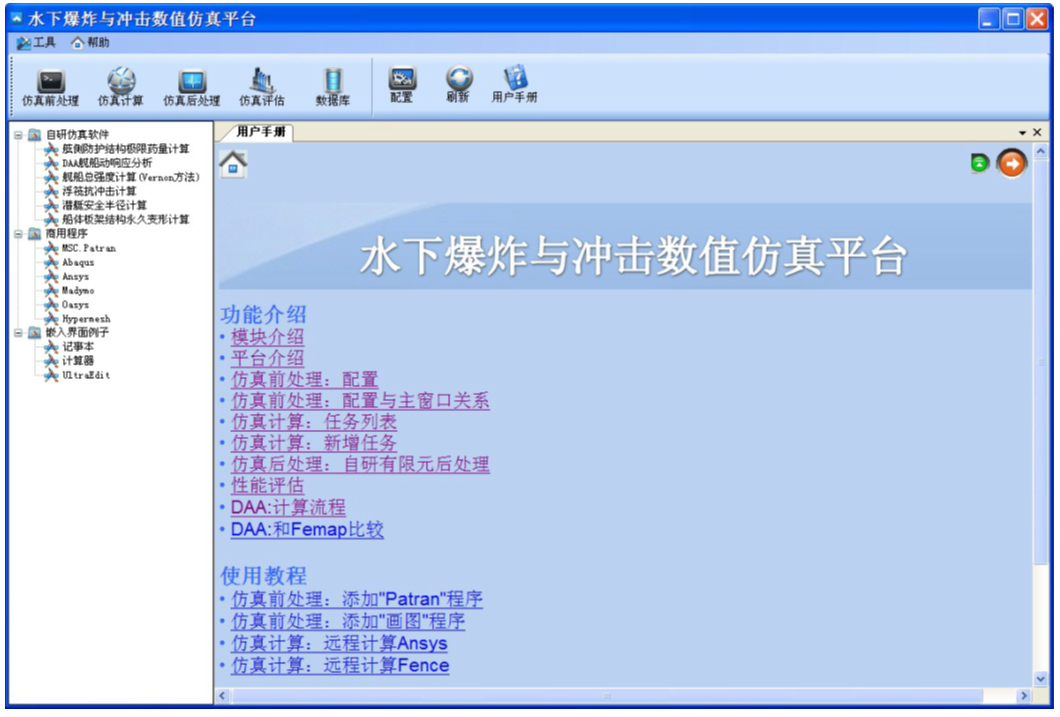

12. Test equipment: Simulation platform for underwater explosion design and evaluation

Main systems:

• Multi-CPU computer cluster;

• Underwater explosion test database (self-developed software);

• Underwater explosion load prediction software (self-developed software);

• Impact environment prediction software (self-developed software);

• Structural explosion resistance design and evaluation software (self-developed software);

• Impact resistance design and evaluation software for floating raft and equipment (self-developed software);

• Human dynamics simulation software (commercial software);

• Evaluation software for explosion and impact resistance of ship (commercial software plus self-developed software);

• Underwater weapon explosive power evaluation software (self-developed software);

Capabilities:

• Database sharing;

• Impact environment prediction;

• Prediction of explosion shock wave and bubble load in water;

• Explosion and impact resistance design and evaluation of structures;

• Impact resistance design and evaluation of floating raft and equipment;

• Personnel impact protection design and evaluation;

• Evaluation of explosion and impact resistance of ship;

• Evaluation of underwater weapon explosive power evaluation;

Contact:

Tel. /Fax: 0510-85558710

Mobile phone: 15852708586 (Liu)